Open-Loop to Closed-Loop Scrubber Conversion

Working with leading scrubber manufacturers, shipowners, and shipyards, LiqTech has many years of experience providing sustainable marine scrubber wastewater treatment systems for closed-loop scrubbers.

Do you have a vessel equipped with an exhaust gas cleaning system (scrubber)? Do you want to be future compliant with IMO regulations and save the ecosystem?

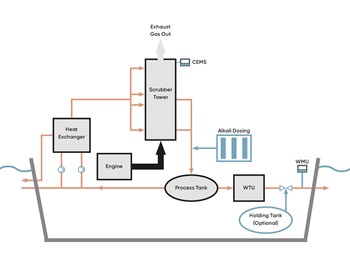

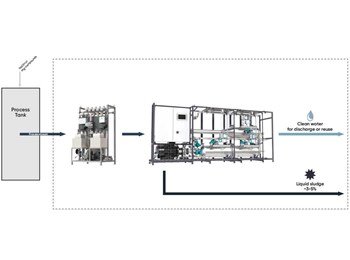

We are ready to convert your open-loop scrubber into a closed-loop system or hybrid scrubber. It is a compliant solution that allows vessels to operate on heavy fuel oil (HFO) and discharge clean water. With over 20 years of experience in the filtration industry and +250 marine scrubber wastewater treatment systems installed, we can provide you with an IMO-compliant scrubber water treatment solution.

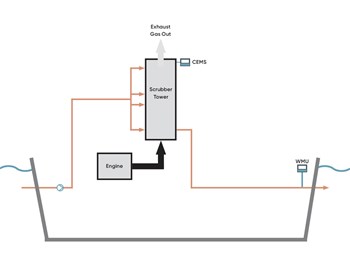

Open-loop scrubbers have been subject to much debate, as they produce large amounts of wash water effluent, which is discharged into the sea, usually without any treatment. In open-loop mode, scrubbers discharge sulfuric wash water warmer than ambient seawater and contain suspended particulate matter, PAHs, and heavy metals. By converting into a closed-loop or hybrid scrubber with an open-loop retrofit, you can operate in zero-discharge mode (water reuse) or allow clean water for discharge without the pollutants that damage ecosystems and harm wildlife. Sludge and wastewater (bleed-off water) can be stored onboard and discharged shoreside.

Be future compliant with a LiqTech open-loop scrubber conversion solution.

The IMO is already working on an approved work plan focusing on harmonizing the rules for scrubber wash water discharges. They have sharply downgraded the limits of allowed sulfur content in marine exhaust gasses from 3.5% m/m to 0.5% m/m in the IMO 2020 regulations. The strict regulations are globally applied to all sizes of ships. Furthermore, in the Emission Control Areas, the upper limit for sulfur content in the marine exhaust is a maximum of 0.1% m/m. With an open-loop scrubber conversion from LiqTech, you will be able to comply with both the IMO regulations and the Emission Control Areas and be prepared for the future. Learn more about the IMO Sulfur Cap.

Our expertise in the marine scrubber industry and wastewater filtration will help you make growth sustainable – both concerning profits and the environment.

- Future compliant with IMO regulations

- Save the ecosystem

- Operate in zero-discharge mode or discharge clean water

- Work with marine and filtration experts