Water treatment for SAGD oil production pre-treatment for RO

LiqTech silicon carbide membrane technology removes solids and oil from Lake Maracaibo surface water. The treated water gets further processed by Reverse Osmosis thus ensuring steam generation.

The Case

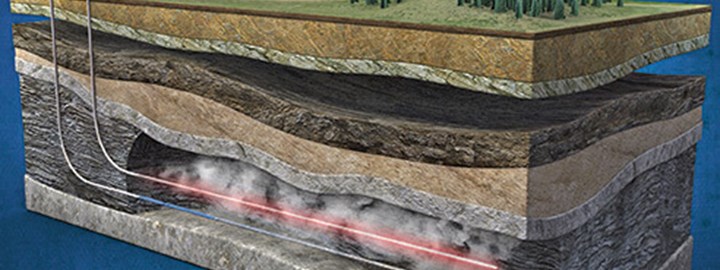

A South American oil company utilizes the SAGD (Steam Assisted Gravity Drainage) enhanced oil recovery process. The SAGD process is used for recovering heavy oil by injecting steam into the reservoir. The steam assists the heavy oil to flow more freely to oil recovery pipelines below steam vents. Significant amounts of water and steam are needed for this production principle.