Produced Water treatment - Re-injection of Produced Water

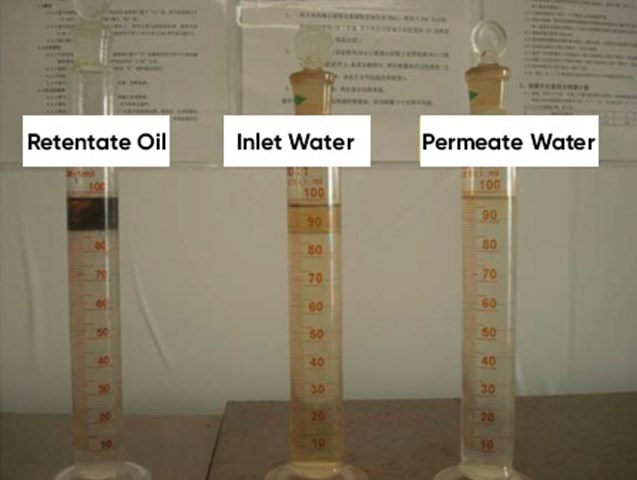

LiqTech Silicon Carbide membrane technology removes Oil in Water (OiW) and Total Suspended Solids (TSS) to very low levels, thus ensuring the highest quality of the produced water to be re-injected. High quality of the re-injection water leads to extended well life and lower oil production costs.

The Case

In offshore oil, oil-soaked particles can reduce reservoir permeability, which increases the risk of undesired fracking of the oil reservoir close to the sea bed. A Chinese offshore oil company wanted to improve the quality of re-injection water, i.e. remove more solids and oil than possible with conventional primary and secondary upstream treatment to reduce the undesired fracking risk.