Achieve Significant Savings in Discharge Fees

Danish dairy has identified a way to reduce discharge fees and chemical consumption in their production significantly.

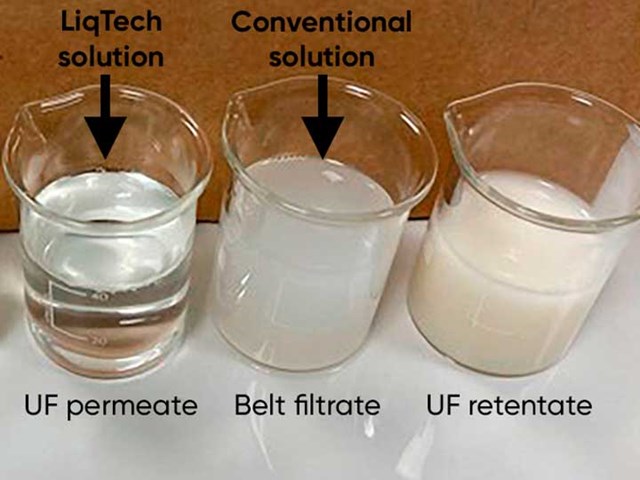

In August 2021, LiqTech conducted a filtration pilot for dairy wastewater treatment at Mammen Dairy. The dairy aimed to increase wastewater production from 72,000 m3/year to 110,000 m3/year within the foreseeable future. Therefore, LiqTech and Mammen Dairy initiated their collaboration to clarify whether this increase was possible based on this case study.

It has been a priority for Mammen to conduct trials with the present composition of production wastewater and the addition of wastewater with higher concentrations of nutrients. The latter would be relevant for combining waste streams to avoid truck discharge of the higher nutrient wastewater.

- LiqTech dairy wastewater treatment system

- Pilot conducted August 2021

- Purpose: Combining two wastewater flows

- Future annual savings: > 100,000€

- Significant COD reduction

- Reduced chemical consumption