What is membrane filtration?

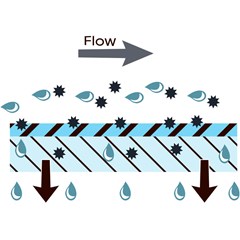

Membrane filtration is a filtration process that removes unwanted particles and contaminants from liquids and gases. The membrane filtration technology is used in many industrial large-scale applications as it enables industries to cost-effectively run cleaner and compliant operations free of harmful particles and contaminants.

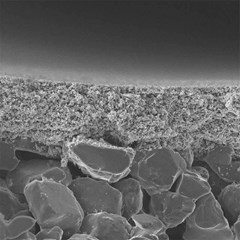

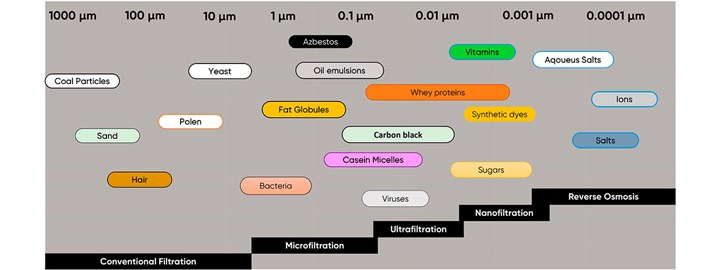

In short, membrane filtration methods employ one or more membranes for the filtration process. A membrane is a thin layer of a material that provides a physical barrier to separate molecules and particles of various sizes and characteristics. Even the smallest elements, such as bacteria and viruses, can be rejected by membranes. A membrane can be made of several organic and inorganic materials and constructed in various module designs.

This enables the membrane to filter different types of liquids or gases. Membrane filtration is a pressure-driven technology. No chemicals are added to treat the water and gases. Chemicals are only needed for membrane cleaning to maintain superior hygiene. Thus, it is a clean technology, securing a greener future.

Membranes can either be produced from organic or inorganic materials. Organic membranes are polymer membranes and are mainly used for liquid filtration. A polymer membrane is a semi-permeable filter media made of polymeric materials such as polysulfone, polycarbonate, polyvinylidene fluoride, polyamide, or cellulose acetate. Dive more into polymer membranes here.

An alternative to polymer membranes is ceramic membranes, which can be produced from various inorganic materials. One of the materials is the solid, long-lasting material silicon carbide (SiC). SiC is the second hardest material in the world, and SiC membranes are rapidly emerging as it provides some unique advantages compared to traditional ceramic and polymeric membranes. This is the membrane LiqTech is specialized in. Dive into the details about silicon carbide membranes here.