FIMAFY

Development of filtering technologies for microalgae and sustainable high-quality feed for fry.

There is an urgent need for alternative resources to fishmeal and fish oil to produce fish feed for the aquaculture industry. The resource problem is due to the rapid growth of aquaculture and the fact that catches of fish for the feed industry are stagnating. The idea to use microalgae as fish feed originated from an ongoing EU project, which demonstrates that algae can be grown on processed water from the industry.

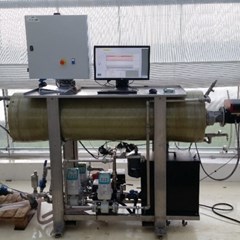

FIMAFY has employed strategies to provide a clear concept for microalgae up-and downstream processing, investigated the shelf-life stability of the dried biomass, and finally evaluated the biomass as a fish feed ingredient. Pre-Gasified industrial process water with a high concentration of ammonia and free from toxic compounds, representing effluent from a local biogas plant, was used as a low-price growth medium. In this study, an innovative downstream process was developed. The process setup includes crossflow microfiltration (MF) by silicon carbide (SiC) ceramic membranes, up -concentration by bowl centrifuge, and finally delicate drying of the biomass by a novel swirl(spin) flash dryer. Harvest trials have been performed on eight different microalgae species (Monodopsis subterranean, Nannochloropsis salina, Dunaliella salina, Phaeodactylum tricornutum, Chlorella Vulgaris, Chlorella sorokiniana, Chlorella pyrenoidosa , and Desmodesmus sp).

All the species showed the same flux pattern while the performance of the harvest was highly species-depended. The recovery efficiencies were higher or equal to 98%, while no cell rupture was observed. The filtration VCR (volume concentration ratio) for microalgae harvest ranged between 10-30, depending on the species cell size, shape, and other parameters. The findings have also been successfully tested on a large scale for Nannochloropsis salina. Energy consumption in this processing technology is estimated at 28% lower than known current processing technologies applied to microalgae. These findings represent the SIC-UF ceramic membrane filtration as a robust and feasible technique for the downstream processing of microalgae.

Participants

- BioMar A/S, Denmark

- LiqTech International A/S

- IFAU, Denmark

- Ecolipids A/S

- DTU Food

- DTU Aqua