The Hardest Man-Made Material – Silicon Carbide

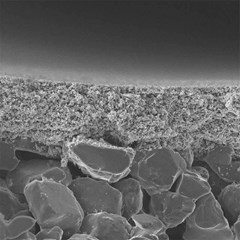

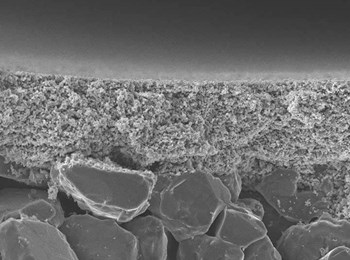

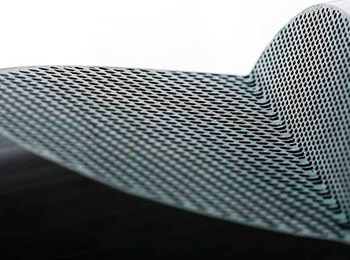

Ceramic membranes can be produced from various inorganic materials. One of the materials is the solid and long-lasting material silicon carbide also denoted SiC – its chemical formula. SiC is rapidly emerging as it provides some unique advantages compared to traditional ceramic and polymeric membranes. Let us dive into silicon carbide and what unique benefits this material offers.

Silicon carbide is a synthetically produced crystalline compound containing pure silicon and pure carbon. Silicon carbide is the second hardest material in the world, only exceeded by diamonds, and the hardest man-made material ever made. On Mohs Scale, which measures mineral hardness based on an ordinal scale ranging from 1-10, SiC scores 9.5, while diamonds score 10. Due to its strength and durability, silicon carbide has been employed for various industrial applications since the late 19th century, when the material was first produced. Silicon carbide was made in an attempt to create artificial diamonds. Now, this element has found its way to ceramic membranes for liquid filtration, providing a porous support structure, which filtered water can permeate. Due to its hardness, SiC ensures thermal and mechanical stability, which is vital for many industrial applications, especially if frequent cleaning or sterilization processes are required. Using solid and long-lasting material secures a high-quality product with long service life and unique advantages.