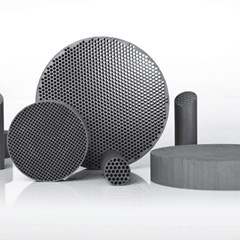

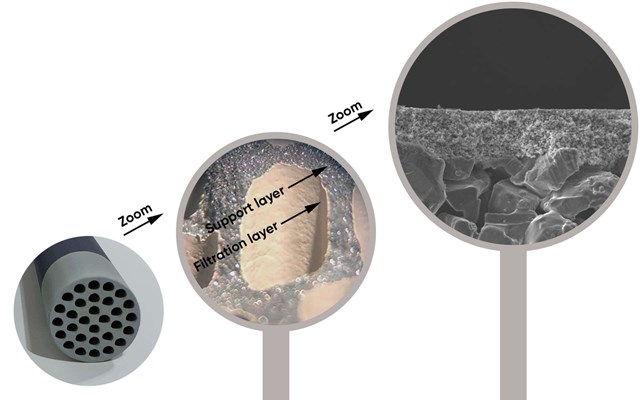

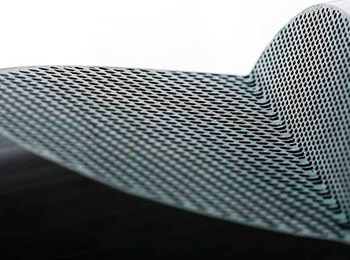

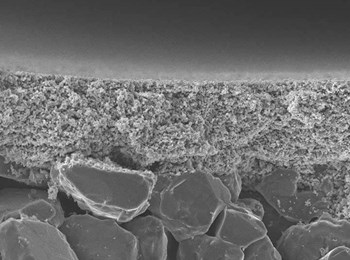

Ceramic membranes represent a revolutionary filtration technology that meets many and-user demands of today and the future by providing current and forthcoming compliance with environmental regulations and sustainable production. In addition to fighting the global problem of clean water by enabling water reuse, recycling, and recovery, ceramic membranes also contribute to low energy consumption, high capacity, and a small footprint. Let us dive into the details of a ceramic membrane.

Ceramic membranes are the most crucial part of a water filtration system.

In these systems, membranes are stored in a housing. The liquid is filtered as the ceramic membranes filter fluids by removing, e.g., suspended solids, oil droplets, oil emulsions, particles, and bacteria. Ceramic membranes can purify liquids at different levels depending on the specific needs and requirements, making ceramic membranes relevant for several tasks in various industries.

Membranes can be used for harsh environments, such as:

Still, they are also applicable in environments demanding high sanitation standards, such as:

Ceramic membranes can be utilized for pre- and post-treatment depending on various processes and filtration requirements.