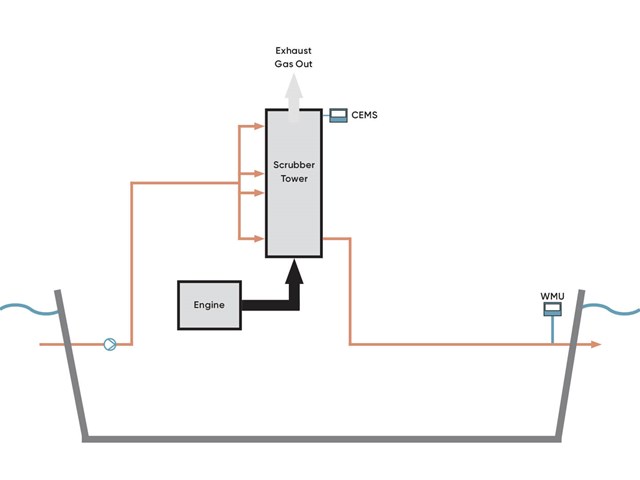

An open-loop scrubber utilizes seawater to scrub the exhaust gases. Thus, this method exploits the natural chemical composition of seawater. The seawater is pumped into and fed to the exhaust gas cleaning systems, and afterward, it is discharged. Still, the discharged water must abide by the IMO’s scrubber wash water discharge limits. Learn more about the scrubber water discharge limits here.

To obtain this water quality, huge quantities of seawater are pumped into the system. This ultimately delivers low turbidity, low pH, low temperature, as well as a low concentration of polycyclic aromatic hydrocarbons (PAHs). As this process demands large quantities of seawater, much wash water is generated, which is both more acidic and turbid than natural seawater. This is discharged overboard without any wash water treatment, which harms ecosystems and wildlife as the water can contain gaseous and particulate emissions, particulate matter (PM), PAHs, heavy metals, nitrate, and unwanted particulates such as soot and ash. Moreover, as this solution requires much water, it requires a large pumping capacity.

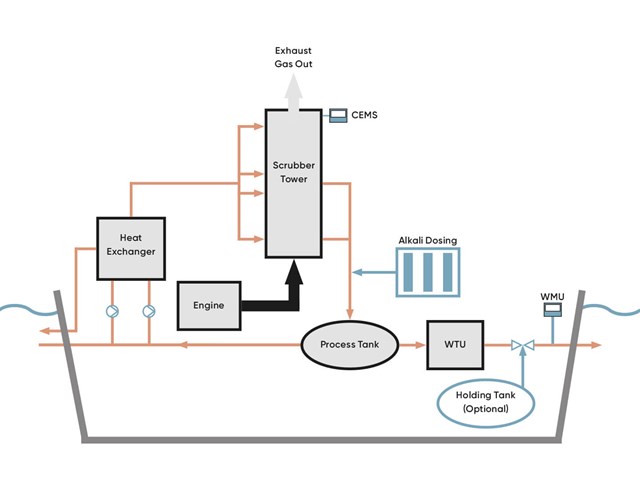

Simply put, open-loop scrubbers move the pollution from air to sea, causing ocean acidification. Several countries have adopted a prohibition on open-loop scrubbers to combat ocean acidification. See the complete list here. If a vessel operating an open-loop scrubber wants to enter these countries or the ECA, it must convert to a hybrid scrubber or a closed-loop scrubber. Alternatively, it can also switch to a more expensive compliant fuel containing a lower amount of sulfur or an alternative fuel with no sulfur. To accommodate this, an increasing number of open-loop scrubbers are designed as hybrid-ready, making it easy for shipowners to upgrade to a hybrid scrubber.

Furthermore, a paper conducted by Ship & Offshore on Open-loop scrubber discharge bans identifies that open-loop scrubbers are ineffective if salinity levels are low. If salinity is low, more water must be pumped into the system. Both freshwater, brackish water, and seawater are not adequate for an open-loop scrubber at high ambient temperature. Therefore, an open-loop scrubber is highly dependent on its operating conditions. This makes it an inadequate technology for areas where the salinity levels are low.