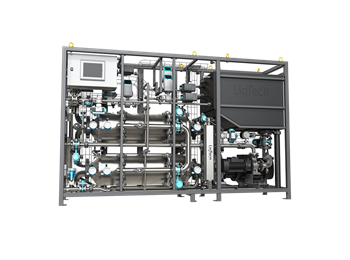

The water treatment solution from LiqTech secures compliance with environmental requirements and reduces handling costs of scrubber sludge

The Case

Ships trading in designated emission control areas will have to either use fuel oil with a sulfur content of less than 0.10% (MGO) or to comply with the SOx requirements by using an exhaust gas cleaning system, or “scrubber.” There is a significant cost difference between low sulfur fuel and the cheaper conventional fuel (heavy fuel). By installing scrubber systems, vessel owners can comply with the new IMO requirements and at the same time benefit from the cost advantage of using conventional heavy fuel.

LiqTech has delivered numerous scrubber wastewater treatment systems to be integrated with scrubber towers. The combined scrubber and wastewater treatment solution reduces sulfur emissions in the exhaust gas and turbidity together with polyaromatic hydrocarbons (PAH) in the discharged wastewater.