Materials and Components

The membranes are made from silicon carbide material which proves to be extremely robust with high permeability and stable flux. Further, the ceramic membranes are chemically inert and very temperature resistant.

Membrane multi-housings are made of glass fiber reinforced plastics (GRP) and single housings of polypropylene. Piping is made of polyethylene and all-welded by our certified craftsmen on-site.

Pumps are high-efficient Grundfos in duplex steel grade with ABB motors.

All components and pipes are mounted on stainless steel SS316L frames and supports.

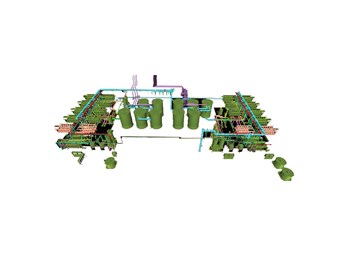

Modular Systems

The filtration systems are made in semi-dead end configuration for particle removal utilizing our OD25mm CoMem UF SiC membrane in a 99X GRP multi-housing in racks of 6 housings.

The cross-flow dewatering system is based on the OD146mm CoMem UF SiC membrane in a PP single housing in racks of 6 and multiple trains.

Cleaning Method

The system is built with Grundfos DDA and DMX dosing pumps for membrane cleaning. Further LiqTech supplied chemical storage tanks with thermal insulation and heating coils including CIP storage and waste handling tanks - all fabricated in-house and in PE material.