What are ceramic membrane filters?

Ceramic membranes are used for liquid filtration by various industries both in wastewater treatment and purifiying liquid products like phosphoric acid. Ceramic membane filtration systems help to ensure a high-quality end product; they also work to optimize your production.

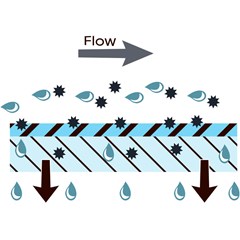

Ceramic membrane filtration technology represents an innovative liquid filtration technology capable of removing suspended solids, oil droplets, oil emulsions, particles, heavy metals, bacteria, and viruses. The technology is used in many large-scale industrial applications to treat various types of water and wastewater. Within water treatment, membranes can remove waterborne diseases and contaminants to control and prevent diseases. Within wastewater treatment, membranes are used to comply with environmental regulations and enable wastewater reclamation and reuse for improved OPEX.

Ceramic membrane filters are made of inorganic materials such as silicon carbide, zirconia, alumina, or titania. The colloidal suspension is placed on a porous support structure, taking various dimensions such as tubular, flat sheet, and disc. These geometries enable different liquid filtration principles so various liquids can be treated most effectively.