Tubular membranes are the most common ceramic membranes. These are designed to remove suspended solids, oil droplets, and oil emulsions. Tubular membranes are ideal for treating produced water in the oil and gas market and industrial wastewater treatment.

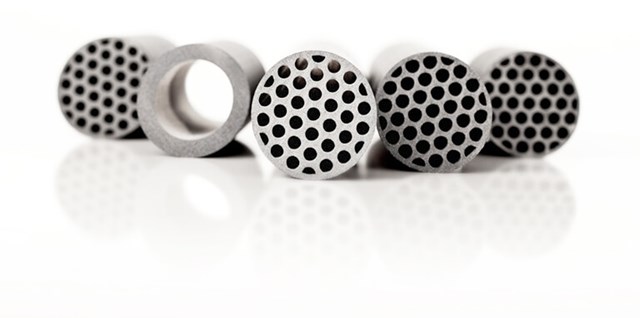

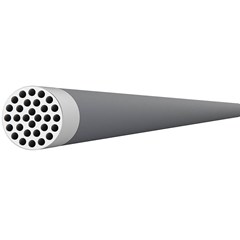

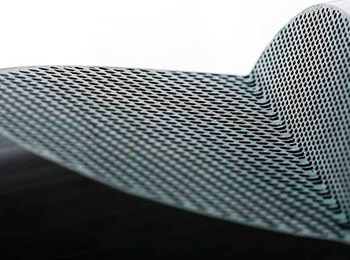

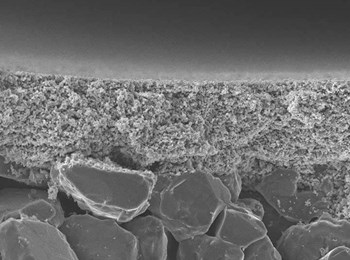

The tubular membrane is designed as a long tube and is coated on the inside of the membrane. . Learn more about membrane coating here. There are two types of tubular membranes: a honeycomb structure and a monotube structure. The honeycomb membrane is a ceramic membrane with several parallel flow channels. A monotube structure is a ceramic membrane with one large flow channel. The honeycomb membrane with 30 flow channels is the most popular membrane type of all ceramic membranes. Due to the many flow channels, this membrane provides a large membrane surface area of 0.33 m2 for liquid filtration, making it capable of filtering a significant amount of liquid, although solely taking up a small footprint. This ensures a highly efficient and compact water filtration process. A whole membrane housing containing 99 ceramic membranes provides a membrane liquid filtration area of an impressive 32 m2.

The tubular membrane is typically used for crossflow configuration, which is the filtration type that is used the most. Still, it may also be used as dead-end filtration. These filtration types are denoted inside-out filtration because the liquid is filtered from inside the membrane and permeate flows outside. Dive more into the membrane filtration principles here.

In the honeycomb ceramic membrane, several parallel flow channels run through the membrane. Pressure from one end of the membrane will make the feed stream flow through the membrane, and this will be separated into permeate and concentrate. Learn more about how ceramic membranes work here.

The benefits of a tubular membrane counts:

- Large liquid filtration area

- Small footprint

- Can be used for both crossflow and dead-end filtration