Marine Scrubber Water Treatment System

At LiqTech, we have long-term experience working with top marine scrubber manufacturers, shipowners, and shipyards, and we have a market-proven solution to obtain constant IMO compliance.

In January 2020, the International Maritime Organization (IMO) implemented a new lower cap on sulfur emissions for international shipping to obtain a cleaner shipping industry. The regulations are even stricter inside the Emission Control Areas (ECA). This sets new standards for how ships should treat their marine scrubber wastewater.

We are here to remove unburned fuel oil, soot particles, ash, and heavy metals from marine scrubber wastewater and take an active role in reducing world pollution. We are sharply focused on the industries where we believe our technology and application expertise can make the greatest difference. Flexible set up to deliver to your special needs - wherever you are. And proud to be pioneers when it comes to solving complex filtration challenges.

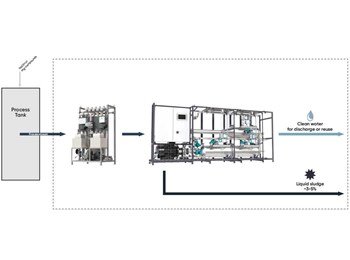

LiqTech offers complete wastewater treatment solutions consisting of:

- Coarse pre-filtration

- Fully automated SiC membrane system

- Module for dewatering of membrane reject

LiqTech has developed a compact and efficient marine scrubber water treatment system for both closed-loop and hybrid scrubbers that outperforms discharge limits regulated by the IMO. Working with market leaders for several years, we have successfully installed retrofit and new-build marine scrubber water treatment systems on hundreds of vessels.

- 12-18 month ROI

- Ideal for retrofit installation

- Future-proof solution

- Selected by market leaders

- Guaranteed compliance with IMO discharge regulations

- Market leader with +250 systems in operation