Reuse of Flue Gas Condensate

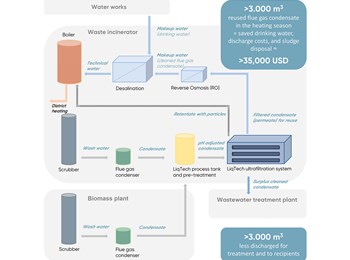

Danish combined heat and power plant has identified multiple ways to reuse ultra-filtrated water as well as energy from their waste incineration and biomass plants.

At the end of 2014, a new flue gas condensing plant was implemented at the incineration plant, primarily to recover energy for use in the district heating system – thereby increasing the plant’s overall efficiency. At the same time, they chose to install a system with ceramic silicon carbide (SiC) membranes from LiqTech for ultrafiltration (UF) of the flue gas condensate, which contains particles, organic matter, salts, and harmful heavy metals.

- Ultrafiltration with cross-flow silicon carbide membranes, buffer tank, integrated backwash, and Cleaning-in-Place (CIP)

- Installed in 2015

- Capacity of 6 m3/h

- Annual savings >35,000 USD from saved drinking water (approx. 3,100 m3), less wastewater, and no sludge for disposal