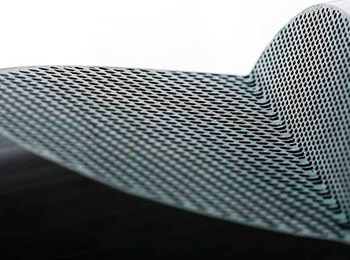

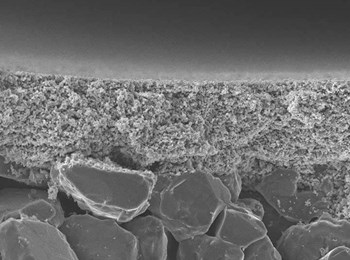

Clean water is a scarce resource, and ceramic membranes are vital in solving this massive global problem. The membranes make up a liquid filtration technology heavily applied in industrial environments as ceramic membranes deliver high-quality and high-endurance liquid filtration. Feedwater enters the ceramic membranes, and the outcome is separated, permeate, and concentrate. However, this process has many more details, so let us dive into how ceramic membranes work.

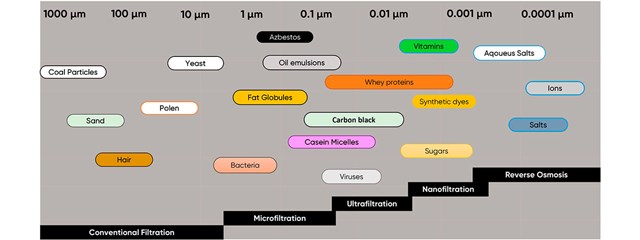

Ceramic membranes can remove multiple objects, such as suspended solids, oil droplets, oil emulsions, particles, and bacteria. Likewise, ceramic membranes can purify and clean fluids at different levels depending on the specific filtration requirements, making membranes highly relevant to numerous tasks in various industries.

Let us dive into the water filtration process.