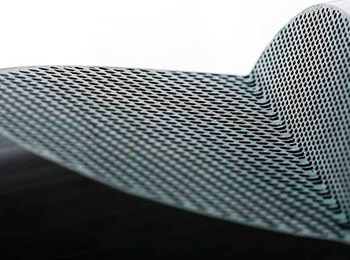

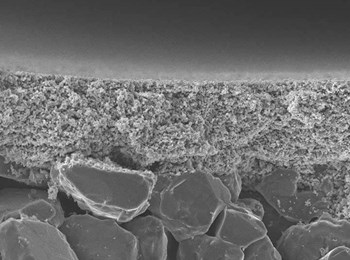

Built on LiqTech’s unique, patented silicon carbide (SiC) ceramic platform, our filtration technology delivers consistent, continuous removal of fine particles, oil droplets, emulsions, and suspended solids — even under fluctuating feed conditions. Designed for high-throughput operation, it enables premium liquid filtration, supporting water reuse and the recovery of valuable resources from wastewater streams.

The technology is deployed in engineered filtration systems for demanding applications such as scrubber wash water treatment, produced water for discharge and reinjection, pre-treatment for reverse osmosis (RO), and polymer-flooded streams. With proven experience across onshore and offshore environments, LiqTech’s SiC platform is trusted to handle challenging produced water streams, including fracking, gas condensate, and complex oil emulsions.

Compared to traditional separation methods such as microflotation and walnut shell filters, SiC ceramic technology provides a more robust and cost-effective alternative — reducing installation complexity and lowering maintenance requirements. The exceptional durability of silicon carbide also minimizes downtime, helping optimize operational stability and total cost of ownership.

Chemically inert by nature, the SiC ceramic platform withstands harsh cleaning regimes, high temperatures, and aggressive process environments. Its high-flux performance, fast recoverability, and long service life allow systems to maintain performance over time — with reduced cleaning frequency, longer operational cycles, and improved uptime.