The hybrid technology membrane (HTM) is revolutionary for the water and wastewater treatment industry because of its unique properties. HTM is revolutionary for improved filtration as it facilitates new separation processes and filtration applications. Let us dive into the details of the hybrid technology membrane.

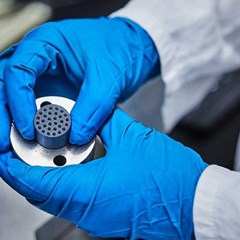

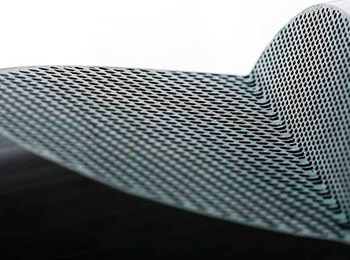

Hybrid membranes are a relatively new approach to manufacturing new, more durable membranes for water and wastewater treatment. Opposite one-component membranes, hybrid membranes are produced of several materials to equip them with improved properties. This leads to enhanced performance and delivers improved permeate quality. In some cases, the HTM can achieve filtration processes that are impossible to reach with conventional filtration technologies. The innovative hybrid technology membranes secure clean water, are durable and cost-effective, and are no longer a complex process.

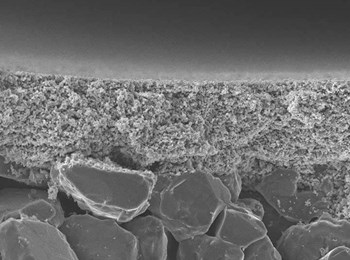

Hybrid membranes can either be produced of polymers or ceramic. Polymeric membranes were previously widespread due to their low manufacturing costs and easy scalability. Yet, polymer membranes lack thermal, chemical, and mechanical strength, making them incapable of handling aggressive fluids from arduous industries such as marine, power plants, and oil and gas. Furthermore, they cannot withstand frequent chemical cleaning, which is crucial to maintain an efficient and hygienic liquid filtration process. Due to these significant drawbacks of polymer membranes, ceramic membranes are becoming more desirable because they propose the most durable separation processes. Furthermore, they can take the lead in cleaning some of the world’s most polluting industries and operates well in harsh environments. Read more about why to use ceramic membranes here.

Hybrid technology membrane benefits:

- Chemical resistant pH from 0-14

- 60 nanometers pore size

- Unmatched flux

- Corrosive resistant

- High permeability

- Long service lifetime

- … and much more