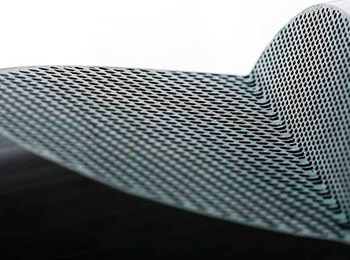

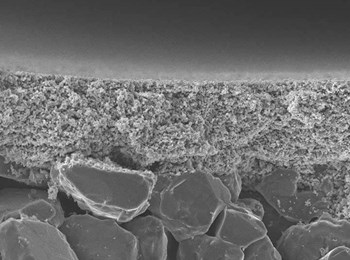

The outside-in filtration principle is denoted outside-in as the liquid is filtered outside the membrane and permeate flows inside the membrane. The filtered liquid can flow through several permeate outlets through the ceramic membrane to a permeate tank. This means that the ceramic membrane is coated with a layer of inorganic material, such as silicon carbide, on the outside of the membrane, which causes the filtration process.

Outside-in filtration is used for submerged modules for vacuum-driven and pressure-driven filtration. The ceramic membranes are submerged into the feedwater in an open tank in these filtration types. The ceramic membranes can be stacked in customized racks, increasing capacity, and contributing to a small footprint. The feedwater is pressured through the ceramic membrane due to a pressure differential caused by a vacuum pump.

Outside-in filtration works best for liquid filtration, where the liquid is not too filled with particles and solutes. Too many particles will lead to frequent membrane fouling and a decreased flux. To maintain a solid and robust liquid filtration performance, the submerged modules are cleaned by a combination of air-sourcing, chemically enhanced backwash (CEB), and periodic chemical CIP, all of which will remove particles and solutes from the membrane surfaces. Flat sheet membranes and disc membranes utilize submerged modules for vacuum-driven filtration.