Hybrid Technology Ceramic Membrane

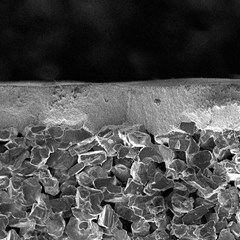

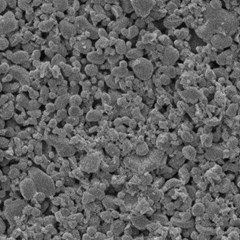

The asymmetric Hybrid Technology Membrane (HTM) combines the desired properties of silicon carbide (SiC) and zirconia (ZrO2) ceramics.

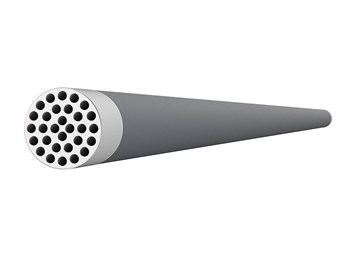

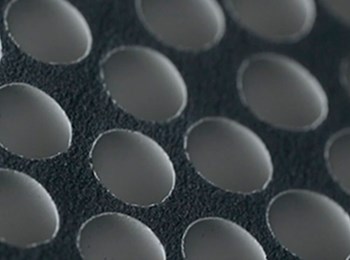

Our Hybrid Technology Membrane (HTM) is an asymmetric ceramic membrane with a pore size of 60 nanometers (nm) suitable for ultrafiltration (UF) technologies. Our HTM represents a patented membrane filtration technology that can purify and clean water and liquids at an extremely pure level. It is a unique hybrid solution combining the best of two worlds – respectively, the best of competing oxide membrane technologies and our commercial silicon carbide (SiC) membrane technology. By combining silicon carbide and zirconia (ZrO₂), our hybrid technology membrane obtains unique and ground-breaking properties. This ground-breaking membrane technology facilitates new separation processes and new filtration applications.

Both silicon carbide and oxide zirconia are chemically resistant in all pH values from 0-14, making the hybrid technology membrane capable of working with all sorts of liquids. The HTM membrane has a long lifetime and can be used in harsh conditions without diminishing membrane performance.

Our hybrid technology membranes are produced in customized geometries, making them adaptable to your specific filtration needs.