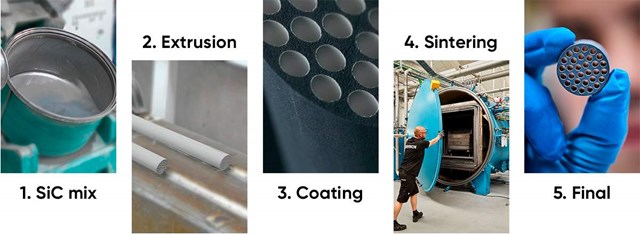

The production ofCeramic membranes is a process of multiple steps, and each step plays a crucial role in achieving durable, high-quality ceramic membranes. Basically. Ceramic membranes are produced in four overall steps:

- A silicon carbide mix is made

- The silicon carbide mix is extruded into the ceramic membrane substrate

- The coating is added to the membrane substrate.

- The membrane is sintered

However, the four steps have many more details, so let us dive into the details.

Silicon Carbide Mix

The first step of the production process is to make a paste with a mixture of multiple raw materials containing silicon carbide powder, dispersant, and solvent. Using the correct raw materials and quantities is crucial to obtain consistent, high-quality membranes. The mix is homogenized thoroughly before a binder is added to strengthen the mechanical stability of the membrane.

Extrusion

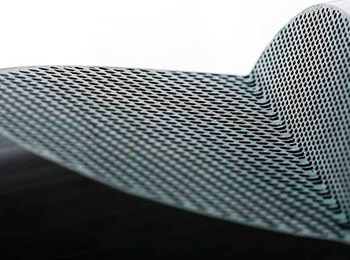

In the next step, the silicon carbide mix is extruded to the correct shape and cut at the right length. It is imperative to extrude the coarse membrane support to produce even the most complex geometries when the mixture is wet. The membrane substrate can be extruded in customized geometries, which is beneficial for various filtration applications. Likewise, the membrane support must be smooth and homogeneous to obtain high flux and mechanical strength. Once the correct geometry is obtained, the membrane substrate should dry. If it is not dried sufficiently, the membrane shape might be damaged, leading to a malfunctioning membrane. Thus, it is essential to obtain complete dryness to have a stable and firm ceramic membrane substrate.

Coating

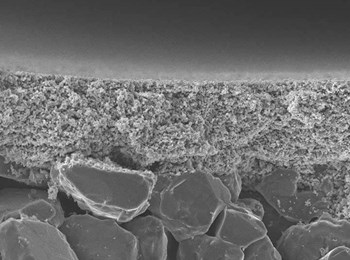

A coating layer is added to the membrane substrate in third phase of ceramic membrane production. The coating controls the membrane pore size and, thus, the selectivity. Moreover, the coating provides ruggedness and durability. Learn more about what the ceramic membrane coating layer does here.

The coating can be added by three different methods:

- Spray-coating

- Dip-coating

- Slip-coating

However, dip coating is the most preferred method due to its simplicity. Still, the selected method should be chosen with care as it affects the thickness of the layer. For instance, the dip-coating technique delivers layers within the range of 0.16-100 microns, while the spray-coating technique delivers layers within 60-200 microns.

Thus, the method should be chosen based on its simplicity, the membrane geometry, and the filtration range it operates within. Furthermore, more layers can be added to produce upper layers with higher selectivity. Typically, the membrane substrate can add up to four coating layers.

In fine, the membrane should dry again to obtain an even coating layer. This is essential because an uneven layer will make different parts of one membrane perform differently.

Sintering

The process’ fourth part includes burning the ceramic membranes in a high-temperature furnace with an inert atmosphere of up to 2100°C for 2-3 days. The process provides durable physical and chemical properties.

In comparison, oxide-based membranes are merely sintered in a furnace of 1200-1600°C. The high sintering temperature of up to 2100°Cas well as the duration of 2-3 days, heavily add to ceramic membranes’ production costs and make the industrial-scale production of SiC membranes costly. Still, the high sintering temperature is necessary to achieve the desired physical and chemical properties of a SiC membrane.