Our Ceramic Membrane Technology

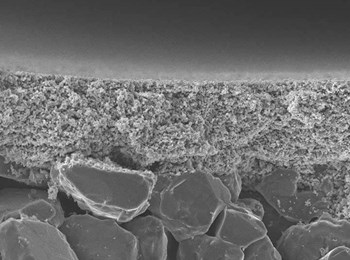

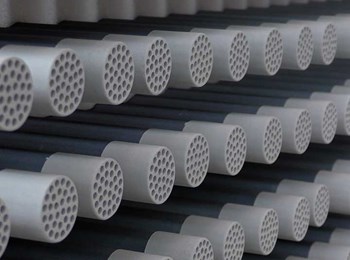

Our SiC filters are manufactured with a ceramic membrane based on our unique, patented silicon carbide membrane technology. We make both the substrate (honeycomb) and the membrane (the part that accomplishes the filtering) solely from the durable and long-lasting material, silicon carbide. This gives our membranes some unique advantages compared to traditional ceramic and polymeric membranes.

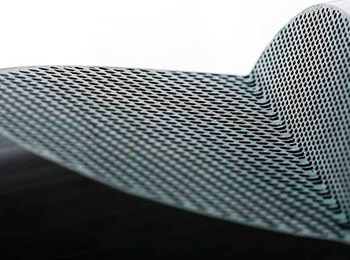

With our SiC technology, the ceramic membrane carrier is based on the so-called honeycomb or monolith structure, as shown in the picture.

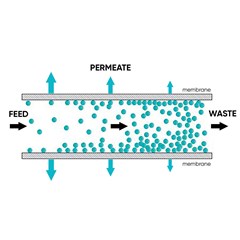

Several parallel flow channels extend through the element in the porous support structure. The feed stream is introduced under pressure at one end of the element and flows through the channels during processing. The portion of the liquid passing through the membrane, known as the permeate, flows into the porous structure of the element. The combined volume of permeate from all flow channels moves toward the outer shell of the monolith support and is removed continuously.