O-WAR

An Integrated Membrane Process for Oily Wastewater Treatment, Water Reuse, and Valuable By-Products Recovery. LiqTech is leading the EU Fp7 project O-WaR in a consortium that consists of seven other partners, including three SME´s, two knowledge institutes, and two end-users.

The O-WaR (Oily Wastewater Reuse) project aims to develop an integrated process that can efficiently remove highly emulsified oil from wastewater, reuse treated wastewater, recover valuable by-products in wastewater, and reduce volumes of oily waste for disposal.

A large amount of wastewater in oil-in-water is generated in different industries such as vegetable oil, metal processing, transportation, petrochemical, and oil and gas (where the oily wastewater is called “produced water”). These oily wastewaters also feature high chemical oxygen demand (COD) and high suspended solids (SS).

All the industries face the same problems: to separate emulsified oil from water in a cost-effective way and to handle large volumes of oily waste economically.

Conventional approaches for treating oily wastewaters include gravity separation, skimming, dissolved air flotation, de-emulsification, coagulation, and flocculation. Membrane processes are also increasingly used for treating oily wastewater.

Membrane processes exhibit indisputable advantages over the conventional approaches, especially in treating highly emulsified oily wastewater: little energy consumption, small footprint, and most importantly, nearly complete removal of oil in wastewaters.

However, the industries have not widely accepted membrane processes, and the major inhibiting factor for the successful commercialization of membrane processes is membrane fouling. Membrane fouling is caused by the adsorption and deposit of some components in feed water on the membrane surface and/or in the membrane matrix.

Membrane fouling results in membrane flux decline over time and eventually membrane replacement (after several chemical cleaning cycles). Although ceramic membranes, due to their hydrophilic membrane surface, are less prone to fouling than polymeric membranes, quickly declined fluxes of ceramic membranes have also been observed in many oily wastewater treatment studies 1,2,3.

Another major problem associated with all the oily wastewater treatment technologies is the large volume of oily waste generated in the wastewater treatment. Concentrated oil, COD, and solids in the waste pose enormous challenges for further treatment, and many end-users' direct disposal of oily waste has become common.

In membrane processes, the concentrate stream typically makes 5-20% of the feed water volume, and disposal costs for the concentrate can be very high in most European countries.

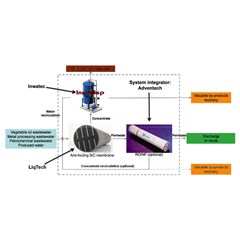

The O-WaR solution consists of

(1) a silicon carbide (SiC) ceramic membrane coated with an anti-fouling layer (AFL) made of nano-particles for oily wastewater treatment with consideration of reuse of membrane filtrate, (2) an innovated Induced Gas Flotation (IGF) technology (InwaSep) for membrane concentrate treatment for significant volume reduction and valuable by-products recovery and (3) a nanofiltration (NF) or a reverse osmosis (RO) unit for further purification of SiC permeate and/or valuable by-products recovery from certain wastewaters.