Revolutionizing Phosphoric Acid Filtration: Unleashing the Power of Silicon Carbide Membranes

As a producer of high-grade phosphoric acids you face significant challenges as striving to purify your product to meet strict requirements in the food, pharma, and lithium-iron-phosphate battery industries. Envision a scenario where your purification plant receive merchant grade acid and find yourself engaged in an ongoing effort to enhance its quality for use in valuable applications like food additives, medical products, and electric vehicle batteries. The acid's quality varies from batch to batch, presenting the need to meticulously eliminate hazardous compounds such as arsenic and sulphur. We know that overcoming the task of precipitating these dissolved substances is just the beginning of your difficulties.

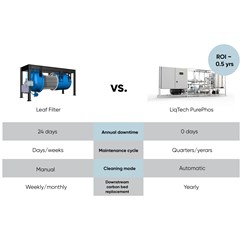

Conventional filtration technologies prove to be insufficient in this challenging environment, leading plants to heavily rely on filter aids. However, this desperate measure brings about a series of subsequent issues. Filter presses experience malfunctions, instrument reliability decreases, and most notably, remnants of the filter aids, such as silica and carbon powder, contaminate the acid, resulting in a lower quality end product. The consequences are significant: costly downtime lasting for days each month and a plant that constantly grapples with filter cleaning and equipment maintenance, causing delays.