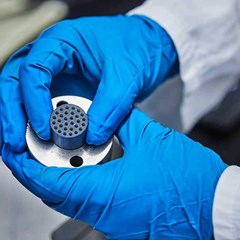

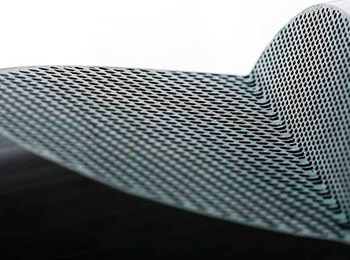

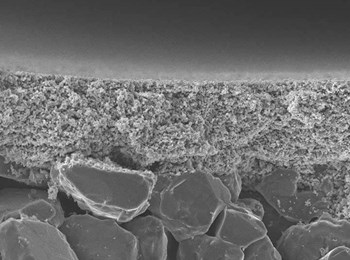

Membrane technology is used in industrial liquid filtration and purification. The membranes can be made of silicon carbide or polymeric material; however, using silicon carbide membranes in your operation rather than traditional ceramic or polymeric membranes delivers significant advantages. Dive into why you should use silicon carbide membranes in your process and what benefits ceramic membranes provide.

Currently, clean water is a scarce resource, and several places worldwide are already experiencing water crises. This negative development is not only seen in developing countries – it affects everyone everywhere. Rapidly, the water demand continues to grow because of the increasing population growth. Therefore, we must manage our water efficiency and sustainably to sustain human life. Ceramic membrane technology is crucial to managing our water effectively and sustainably. The ceramic membranes can concurrently optimize your operation by delivering several significant benefits.

The video below explains how membrane technology enables sustainable water resources management.